●Material Selection

The first step in the production process is choosing high-quality silicone material. Silicone is a synthetic polymer that is known for its flexibility, durability, and resistance to heat and water. It is available in various grades, ensuring the wristbands are safe for use and comfortable to wear.

●Molding Process

The silicone material is mixed with pigments to achieve the desired colors. The mixture is poured into custom molds, which are typically made of metal or plastic. The molds have the shape and size of the wristbands, including any raised or debossed designs or messages. These molds are then placed in a heating press where the silicone is cured and solidified into the desired shape.

●Customization

Once the silicone wristbands are formed, different customization options can be added. This includes embossed (raised) designs or messages, debossed (engraved) designs or messages, or printed designs using screen printing or UV printing techniques. This allows for personalization and branding elements to be incorporated into the wristbands.

●Finishing Touches

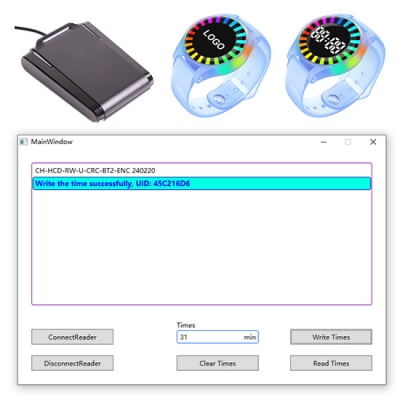

After the customization, the wristbands are inspected for any imperfections or defects. They are then trimmed to remove any excess material and smoothed out for a comfortable fit. Optional features like adjustable straps, barcode labels, or RFID/NFC chips can also be integrated into the wristbands during this stage.

●Packaging and Distribution

Once the silicone wristbands are finalized, they are packaged according to the desired quantity or customer requirements. They can be individually wrapped or grouped together in sets. The packaged wristbands are then ready for distribution through various channels, such as retail stores, events, or online platforms.

Silicone wristbands are popular for a wide range of applications, including

◆Event Wristbands: They serve as identification and access control for concerts, festivals, conferences, and sporting events.

◆Promotional Merchandise: They are used as giveaways and promotional items for brand awareness and marketing campaigns.

◆Fundraising: Silicone wristbands are often sold to support charitable causes and fundraising initiatives.

◆Medical and Healthcare: They can be used as medical alert bracelets or wristbands for patient identification and tracking.

En résumé, les bracelets en caoutchouc sont fabriqués selon un processus de sélection des matériaux, de moulage, de personnalisation, de finition et d'emballage. Grâce à leur polyvalence, leur durabilité et leurs options personnalisables , les bracelets en silicone continuent d'être un choix populaire pour divers usages et événements. En tant que l'un des principaux fabricants de bracelets intelligents, Meihe dispose d'équipements de production avancés et d'un personnel de direction de premier ordre, et a actuellement fourni des centaines de millions de produits RFID à ses clients et partenaires. Nous avons tout ce dont vous avez besoin dans un bracelet en silicone. Tous les textes, logos, images ou designs personnalisés sont tous disponibles pour produire ce dont vous avez besoin. Contactez-nous dès maintenant pour en savoir plus sur les bracelets en silicone !